08 November 2023

NOW NEW: BMO INFINITY.

Flexibly expandable automation solution for pallets and workpieces.

Expansion of hybrid automation into a flexible production system for even more flexibility in the mixed production of single parts and series.

BMO Automation from Neederwert, Netherlands, has been an important automation partner of HEDELIUS for many years. BMO hybrid automation of the Platinum or Titanium type is now in use on over 50 HEDELIUS 5-axis machining centres.

With the new Infinity series, it is now possible to realise even more unmanned processing time with our machines thanks to the increased pallet and workpiece storage space.

The system also meets the wishes of many users to link several machining centres from a series as a flexible production system.

Highlights of the BMO Infinity.

Configurable shelving system.

The centrepiece of the system is a freely configurable rack for holding pallets and beams with a grid for storing workpieces for direct loading. The integrated automatic height measurement ensures optimum utilisation of the rack storage.

Flexible manufacturing system.

The number of shelves can be freely configured in different widths. As an option, the robot can be mounted on a floor trolley. This creates a flexible production system for multi-machine interlinking.

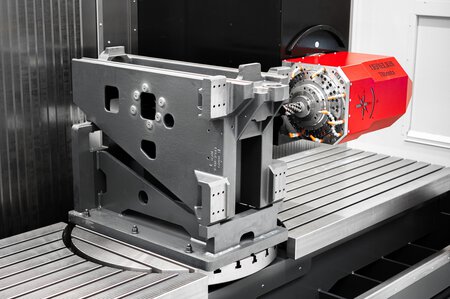

Variable gripping systems.

The trays with the workpieces to be processed are placed directly in front of the respective machining centre for processing. Servo-controlled, automatically adjustable grippers allow several machining centres to be loaded effectively, even with short cycle times.

Optional use of pallets.

Workpiece pallets are used to close heavy workpieces or individual clamping devices.

Examples of the BMO Infinity's equipment.

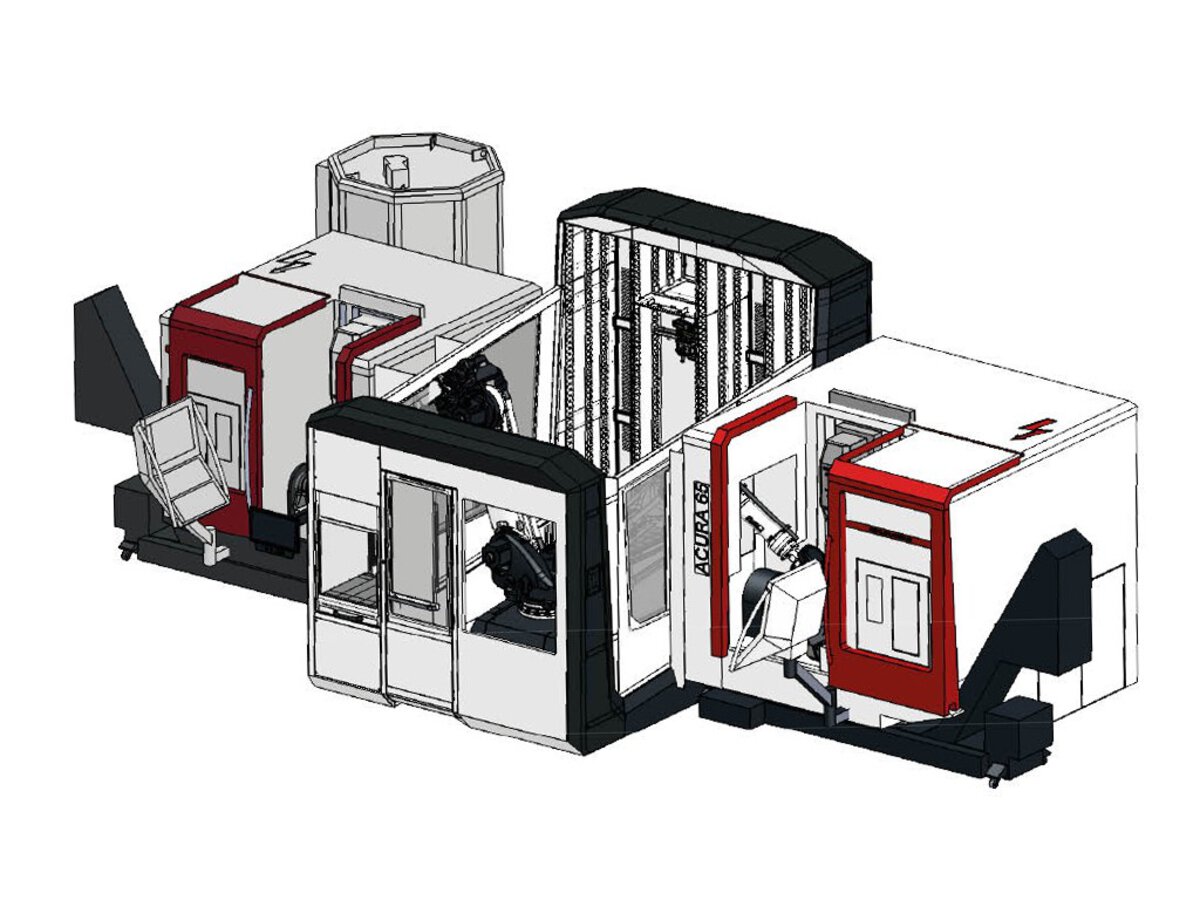

Equipment example 1

BMO Infinity as a Twinner version for loading an ACURA 50 and an ACURA 65.

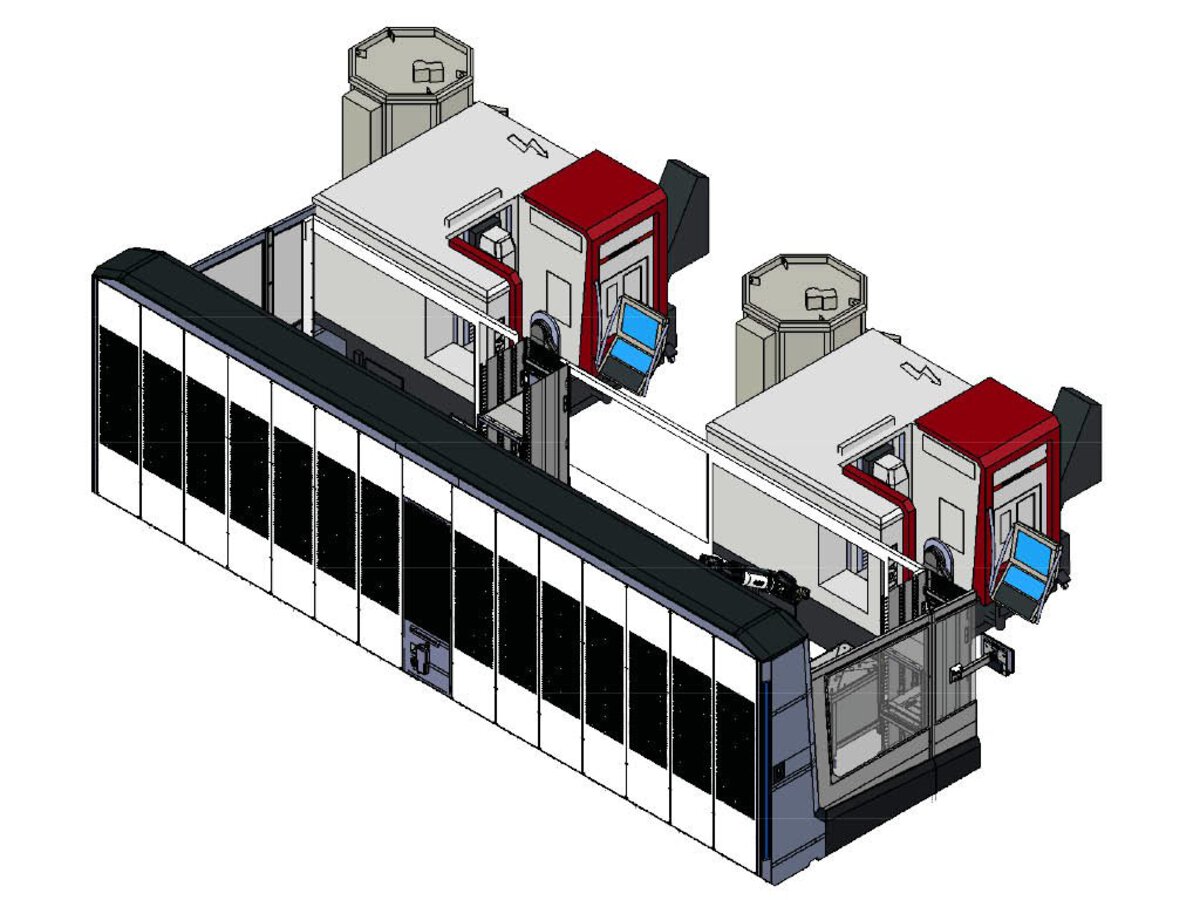

Equipment example 2

BMO Infinity as a flexible production system with floor trolley for loading two ACURA 65s.

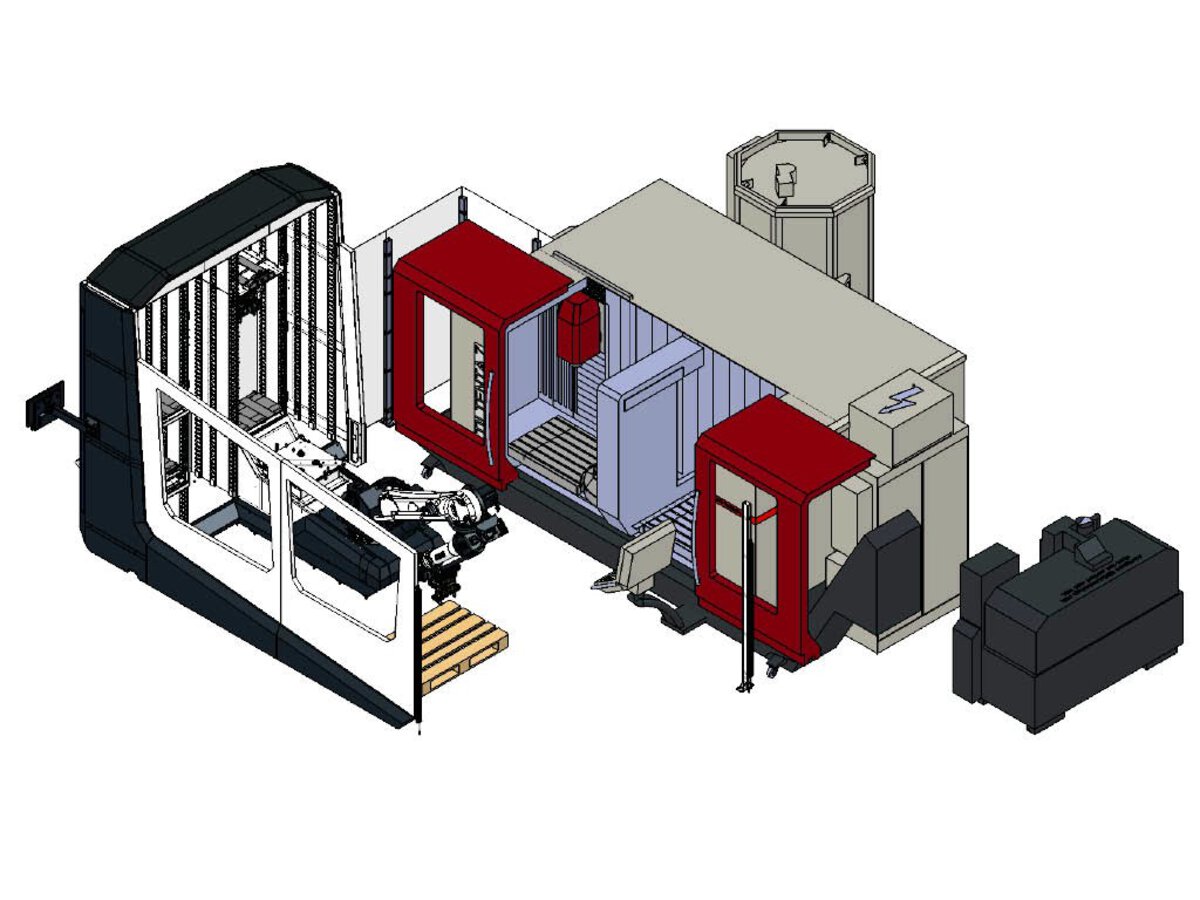

Equipment example 3

BMO Infinity for loading a TILTENTA 7 with additional Euro pallet module to expand capacity.

Request for the BMO Infinity.

Are you interested in the BMO Infinity and would like more information or a customised quote? Our team will be happy to answer your questions and help you close your next step in machining technology.

Please complete the form and we will contact you promptly to discuss your requirements and provide you with all the information you need.

More news.

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?