24 January 2022

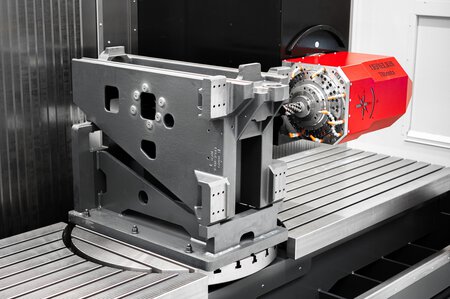

NEW: Integrated cone release function in the tool magazine.

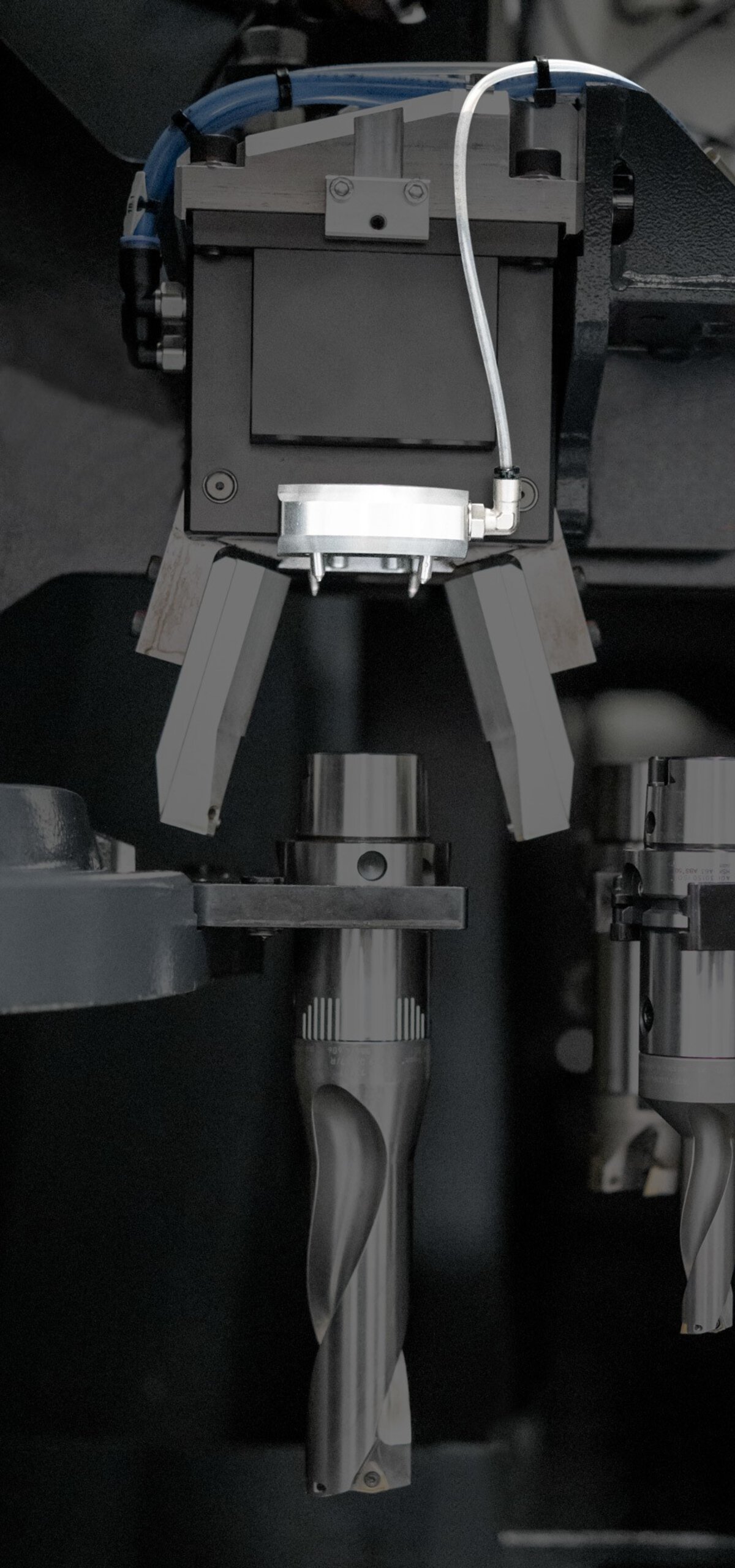

Additional blow-off function with flow-optimised nozzle.

Blowing off the taper by the spindle during tool change has always been standard on HEDELIUS machining centres. In volume machining of aluminium, however, it can happen that chips get onto the steep-angle taper or the face of a tool, e.g. due to the movement during tool change or dripping coolant. In automated production in particular, this can reduce process stability and lead to rejects. For this reason, HEDELIUS now offers an optional additional blow-off function in the tool magazine, which blows off the taper a second time with a flow-optimised nozzle when it is placed in the tool chain.

More news.

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?