03 December 2020

Live at the HEDELIUS demonstration centre.

High-end automation cell with 33 pallets and 480 tools.

Live in the demonstration centre

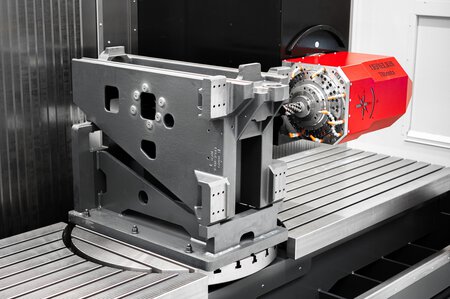

The linking of an ACURA 50 EL and an ACURA 65 EL via the Indumatik Light 120 pallet handling system is now ready for demonstration. The Indumatik Light 120 loads the 5-axis CNC machining centres with 400 x 400 and 200 x 200 mm pallets. The demonstration system stores a total of 33 pallets (12 units of 400 x 400 mm and 21 units of 200 x 200 mm). Other pallet dimensions are of course possible. Both processing centres are equipped with an HSK A63 spindle with 18,000 rpm and a standby magazine. A total of 480 tool positions are available on both CNC machines (235 tool positions on the ACURA 50 and 245 tool positions on the ACURA 65).

The innovative ACURA concept with side loading enables the automation of an ACURA 50 EL and an ACURA 65 EL with a pallet magazine or a robot cell. Do you have full order books? No problem, both machines run automatically around the clock. Do you need to run in new parts? No problem, one machine runs automatically and you can run your parts in at your leisure on the other. Does your customer need a single part quickly? No problem, one machine continues to run automatically and you produce the single parts on the second. As at least one machine is always running automatically, you can optimally utilise the full capacity of an automated system. The staged investment option is also well released. At the beginning, for example, a machining centre plus automation is purchased. As soon as the orders increase, a second machining centre is added to the system. The space requirements and scope of investment are significantly lower than those of a classic linear interlinking system.

Gallery.

More news.

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?