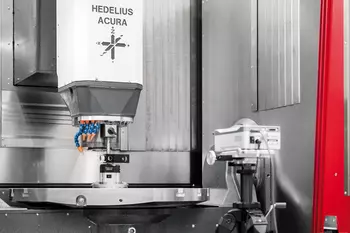

Machining centre with rotating/swivelling table: ACURA 85 EL

The advantage of the ACURA EL concept is that loading from the side allows full access to the work area for set-up and control work, but also for single part production during the day shift, for example. Even crane loading of the machine is possible without restrictions. Another advantage of the 5-axis machining centre (depending on the selected automation) is the visibility of the work area and thus optimised process control during set-up on the automation.

Your advantages with the ACURA 85 EL

- Automation with pallet handling system or robot

- Loading from the left side of the machine

- Prepared automation interface

- Side loading opening with opening height of approx. 1100 mm

- Suitable for numerous pallet handling systems or robot systems

- Pneumatically activated stainless steel loading door on the left in the work area

- 4-fold rotary transfer for pneumatic systems in the machine table for activating zero point clamping elements or power clamps

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

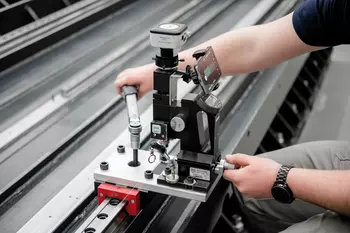

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.