14 March 2023

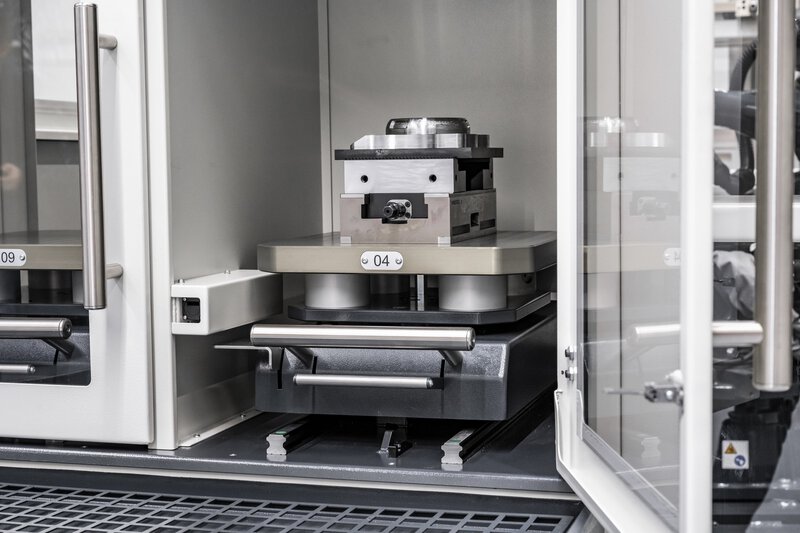

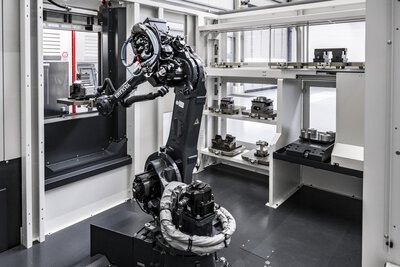

MULTI-PALETHON magazine system

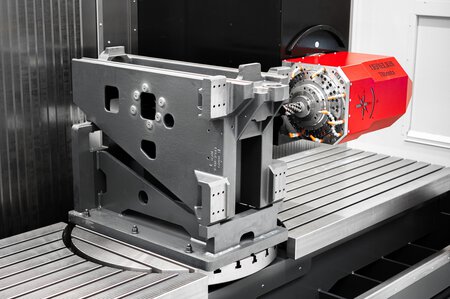

MARATHON RZ430.

Automation with 6-axis robot.

The MARATHON RZ multi-pallet magazine system will be ready for demonstrations just in time for the in-house exhibition - the first in-house automation system open to a 6-axis robot. With up to 34 pallets of 400 x 400 mm each and a clamping height of 400 mm, the system is ideal when single parts need to be produced as repeat parts, small series or medium series. Pallet handling is performed by a 6-axis YASWAKA robot with a load capacity of 88 kg (optional 110 kg). Two pull-out storage/retrieval stations guarantee maximum productivity even with short program runtimes.

The MARATHON RZ is perfectly open to the ACURA 50 and ACURA 65 5-axis machining centres.

Technical information.

Gallery.

More news.

We will be on company holidays from 23 December 2024 to 03 January 2025.

Our service will still be available for you on 23 December 2024 and will not be available for you again until 02 January 2025.

Our sales team will be available for you again from 06 January 2025.

In manufacturing companies that mainly produce small batch sizes, every minute of spindle time counts - or so the theory goes. In practice, however, the proportion of productive spindle time compared to working time is often less than 40 per cent. The search for tools, clamping devices and information, as well as set-up, tie up valuable resources and leave many operating companies far behind their potential. There are many ways to sustainably close flexibility - and thus performance - in production. But every manufacturing company is different. The trick is therefore to find your very own recipe for success.

Advancing automation has long since arrived in mechanical engineering and contract manufacturing - but many companies still face challenges, especially when it comes to small batch sizes. While large-scale production is already largely automated today, flexibility in smaller quantities, which are often the order of the day in contract manufacturing, poses a particular challenge. How can automation be made to pay off here too without presenting machine operators with insurmountable hurdles?