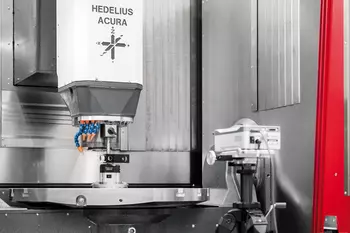

Machining centre with swivelling spindle: TILTENTA 9-4600

With travel paths of 4600 x 900 x 900 mm (x/y/z), the TILTENTA 9-4600 offers plenty of space for a wide range of machining tasks. Be it for the vertical machining of workpieces up to 4600 mm in length or for the economical 3- and 5-axis machining of series parts in oscillation mode.

Your advantages with the TILTENTA 9-4600

- Versatile 5-axis machining centre with swivelling main spindle

- Four axes in the tool and one axis in the workpiece for maximum precision

- Extra-large X travel path of 4600 mm

- Front side processing of workpieces up to approx. 3600 mm

- Optionally with integrated heavy-duty rotary table (table load up to 1800 kg)

- 3- and 5-axis machining in oscillation mode optional

Comparison of the machines.

This is where the machine comparison is created: Add further machines to compare performance parameters.

Gallery of the TILTENTA 9-4600

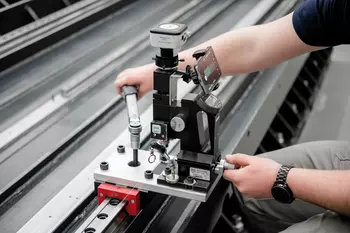

The basis of precision.

Many factors play a role in achieving a certain workpiece accuracy. On the one hand, there are the machines themselves. The type, components and software all have an influence on the machining result. However, there are also many accompanying factors to consider, from the location of the machine to measuring equipment, clamping devices and tools through to the qualifications of the employees.