Automation of 3- and 5-axis machining centres.

The increasing demand for efficient and flexible production requires innovative automation solutions. HEDELIUS offers customised automation systems for all series - ACURA, TILTENTA and FORTE - that open up your 3-, 4- and 5-axis chipping to a new level of performance. Regardless of whether you need to precisely machine small workpieces or produce large components, each series is optimised for different production requirements and can be equipped with our in-house automation systems or proven solutions from renowned partners such as EROWA, INDUNORM, ROBOJOB, BMO and LANG.

While the ACURA series has already been successfully automated with pallet handling systems and robots in numerous operating companies, we are also seeing growing interest in automation solutions for the TILTENTA series. From machining centres with rotating/swivelling table (ACURA), to long-bed milling machines with swivelling spindle (TILTENTA), through to 3-axis milling machines (FORTE) - HEDELIUS offers the right automation solution for every requirement, helping you to optimise your production and remain competitive.

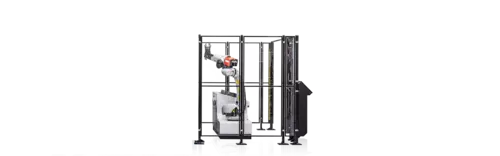

Systems for automated loading with pallets..

If single parts need to be produced as repeat parts or small to medium series, the use of an automation solution with pallets is the ideal solution. One of the main advantages of pallet handling systems is that new workpieces can be clamped or devices converted during production. The pallet stock can amount to several dozen pallets and is based on the average workpiece runtime and the desired total runtime with a minimum of manpower.

Systems for automated loading with workpieces.

Workpiece automation offers you the opportunity to optimise your production and increase profitability. Whether for smaller batch sizes or in large-scale production - with a system based on industrial robots, you can significantly extend unmanned machine runtimes without the need for operating personnel. From handling simple workpieces to serial production: Workpiece automation ensures precision, efficiency and flexibility.

Reasons for automation.

In the current times, entrepreneurs and managing directors are dealing with the challenges in the ranges of personnel, space and productivity on a daily basis. By implementing modern automation solutions, these challenges can be tackled effectively and long-term competitive advantages secured.

Reduce your dependency on skilled labour and use your human resources more efficiently.

Optimise your available space with compact automation solutions that can be perfectly integrated into your production environment.

Increase your productivity through shorter tooling times and continuous utilisation of your machines.

Classification of batch size and variance.

The choice of the right automation system depends on the number of pieces, batch size, running time, dimensions and weight of the workpieces to be produced. HEDELIUS not only develops its own automation solutions, but also works with numerous well-known automation partners to find the optimum solution for every requirement. We offer numerous solutions for small batch sizes with high variance, workpiece handling with industrial robots for large batch sizes and hybrid automation solutions as a combination of workpiece and pallet handling.

By using universal clamping pallets, this automation system is suitable for different workpieces such as sawn parts, welded assemblies or castings, as well as workpieces of widely varying weights.

The focus here is on part families with similar dimensions, weights and blank contours. The workpieces are either gripped directly by the robot and inserted into a device or the workpieces are pre-clamped in a clamp and then the clamp and workpiece are inserted into the machine.

By using universal clamping pallets, this automation system is suitable for different workpieces such as sawn parts, welded assemblies or castings, as well as workpieces of widely varying weights.

Advantages of automation.

By automating your CNC machine tool, you can increase the spindle run times per year and make full use of the maximum capacity of your CNC machining centre without having to hire additional personnel.

CNC automation allows you to significantly increase your production output. Even with small quantities and individual workpieces, workpieces can be processed one after the other without the intervention of personnel. CNC pallet automation or a 6-axis robot take over the loading and unloading of your CNC milling machine. Downtimes and waiting times are reduced. Of course, this is not only useful during the day. Depending on the number of pallets or the size of the parts storage area, an automated machining centre can also run overnight or at weekends. CNC automation allows you to produce at lower unit costs and increase your production output and therefore your turnover and profit.

Achieve higher sales and profits through higher productivity and lower unit costs.

To increase the turnover of your CNC machining centre, you need to increase the number of spindle hours per year. Automation from HEDELIUS fulfils this task.

With our advanced CNC automation solutions from the MARATHON series, as well as our open interface system for third-party providers such as EROWA, BMO, Indumatik or Lang, we will find the right automation solution for you. Let your CNC machining centre work - not only during the day, but also in the evening, at night and at weekends.

Experience live.

Discover the innovative power of HEDELIUS - whether you visit us in person at our technology centre in Meppen or receive a demonstration via live stream from the comfort of your desk. We offer you the opportunity to experience our state-of-the-art machining centres up close and convince yourself of the quality of our products.