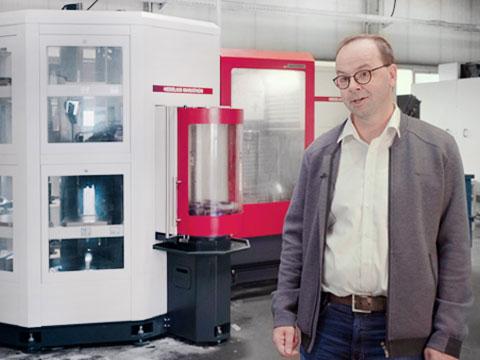

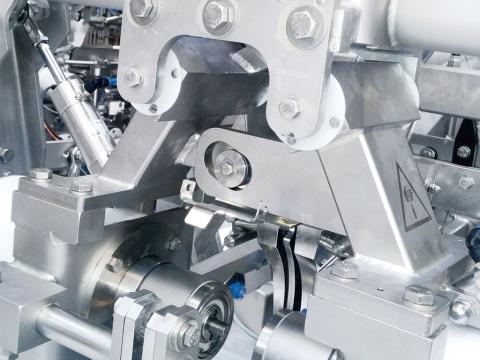

The large TILTENTA stands out as a genuine all-rounder in the machine park at BL Lasertechnik GmbH. Equipped with an extra-large Y-travel path of 1,100 mm, a collision area diameter of 1,450 mm, a liquid-cooled CELOX motor spindle and two integrated heavy-duty rotary tables, the swivelling spindle machining centre is especially useful for powerful and precise production of large, heavy, and complex workpieces. Besides the large machine, there are also two smaller 5-axis machining centres from the TILTENTA swivelling head series, as well as a vertical 3-axis machining centre of the type FORTE 85 Single 1620 for a high degree of versatility available to machining tasks.